4. About the rocky environment of dangerous cellars and caverns

The enclosing

rocks of the risky domestic cellars are very

diverse, which significantly determines the development of the dangerous state

and therefore the prevention activities. Given that a general

description of the various types of rock can be found in the literature, I present their properties

in terms of their effect on underground cavities and cellars.

4.1. Major rock types that surround it

4.1.1. Pannonian sand and clay (Pécs, Érd-high shore, Eger) are typically low

stability, water sensitive and swell. Total dehydration and repeated soaking can cause

very serious damage to underground objects. Cavities created in the clay version are also exposed to

the risk of so-called foot swelling, which must be taken into account when dimensioning the support structures

and revising the cavities. The breakage of the cavities can

be flowing or blocky. In these materials the cellars were

often built with a supporting structure, an arch.

4.1.2. The air-contact surface of the cavity cut

into sedimentary limestone ("lime" limestone

and "sarmatian" limestone)

is damaged, mossed, and the rock loses its strength. Its

bending strength is low, so cracking

(sometimes only a few tens of meters)

of the ceiling formed during the

mining is almost inevitable. Typically,

large cracks and displacements occur in limestone, which at first cause

slow movements. They break down

in blocks. The problem

is the large size of the cavities

as well as

the installation (and thus overload) of the surface above

them. 110 km in Budafok and 32 km in Kőbánya can be found.

Properties of Sarmatian

limestone:

weight: γ = 2,0 - 2.07 t / m3

Uniaxial compressive strength: σc = 3.6 - 8.0 MPa

Tensile strength:

σt = 0.3 MPa

Shear strength:

τ = 0.52 - 0.58 MPa

(source: KBFI-ALFA 1997, 2002)

Sarmatian limestone is

mostly inhomogeneous: from lime slurry to hard limestone,

it can be found in all varieties.

As a result, the various layers

are easily separated, leading to discrete layers.

This phenomenon occurs primarily on the drawn

side of the rock body (in the lower plane

of the headstone, in the side walls

at the point

of protrusion).

4.1.3. The caverns of the freshwater limestone (Budapest I. district,

Eger) are typically naturally formed, and later received various functions (protection, storage) as a result of human activity. The rock forming the hollow of the

cavities is brittle and of low bending strength.

It is sensitive to road traffic

and vibration and transmits

vibration waves far. The rupture usually takes the form

of a coffin lid.

The clay, marl,

which appears as an encrusting rock and is embedded between blocks, is water-sensitive and prone to swelling.

Characteristics of freshwater

limestone:

weight: γ = 2.5-2.6 t / m3

Uniaxial compressive strength: σc = 6.8 - 9.0 MPa

Shear strength:

τ = 0.52 - 0.58 MPa

(Source: FŐMTERV Rt.)

4.1.4. In the volcanic

rock tuffs (rhyolite tuff, rhyodacite tuff) the cavities

were formed primarily through the mining of building stone. The

tuffs are sensitive to water,

their strength in the air deteriorates greatly, and they are characterized by weathering. This phenomenon is found mainly in the surface-related entrance of the cellars. Like sedimentary rocks, tufts have

low tensile strength. The strength properties of tufts vary widely, depending

on their condition and location.

Properties of the rhyodacite tuff (when dry):

weight: γ = 1.33 - 1.45 t / m3

Uniaxial compressive strength: σc = 2.25 - 7.09 MPa

Tensile strength:

σt = 0.52 - 0.97 MPa

Shear strength: τ = 0.35 - 0.50 MPa

(source: GEOSERVICE Gmk 1985)

Characteristics of basalt

tufa (wet or air-dry):

weight:: γ = 1.9 - 2.1 t / m3

Uniaxial compressive strength: σc = 7.35 - 11.08 MPa

Tensile strength:

σt = 0.25 - 1.57 MPa

(source: Réthelyi 1986)

It is characteristic of the rhyodacite tuff that the

main constituents of the feldspar are converted to clay by

moisture. It is important to know

that it is not only groundwater

or rainwater that can cause

this, but also the vapors

that accumulate in the air space of the cellars. As

a result, their strength is significantly reduced, up to

20% of the original strength.

The rock structure of the tuffs allows

the root of the vegetation to penetrate, and this factor also

contributes to the degradation of the vegetation.

The cellars built

in the solid rock environment described above are characterized

by the fact

that the supporting structures (masonry, arches, entrance barriers) are made of materials

extracted from the cut. Therefore,

the process and time course of their failure is almost identical to that

of the parent rock - that is, it occurs

with it.

Also typical of such solid cellar-driven

cellars is that the headstone above

them is usually of low thickness and has significant natural or artificial layers.

The reason for the small thickness

is that most of the cavities were made

for material extraction, ie the extraction man was trying to

extract as much material as

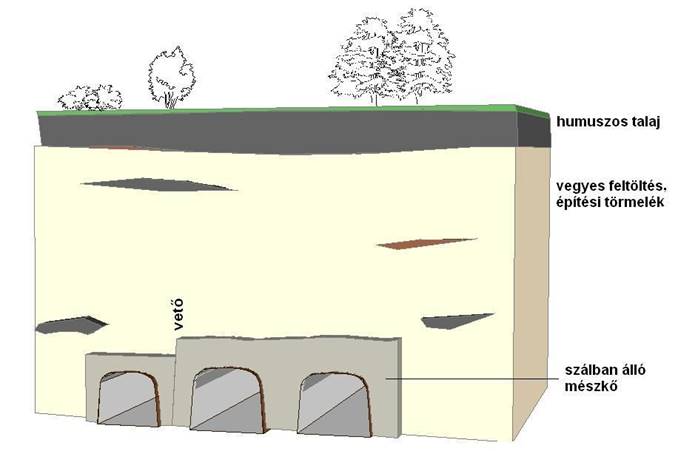

possible from the site. A typical example of this, as well as

the size of the natural and artificial fillings, is the cellar system

located under the Old Hill Park in Budapest's

X. district. The quarry, formerly used for

quarrying and then clay mining, has been filled with communal

rubbish and building debris

since the 1960s. The 12, sometimes 18 meters thick, filling places a significant load on the

headstone of the deep cellars, which

are barely 0.8 to 1.2 meters thick.

The rock environment

of the cellar passages with filling

Budapest, Kőbánya Cellar

system in Óhegy Park

In such a thin

rock body, which is loaded with headstone, bending forces cause vertical cracks and, on its lower plane,

discrete deposits. This process can

also be found in cellars cut into

freshwater limestone and tuff.

Disc separation

Budapest, Kőbánya

4.1.5. More than one

third of our country's territory is covered by loess

soils. Our loess can be divided

into three types. The so-called typical loess (which is typically found in Transdanubia, the Somogyi and Tolna hills, along the Danube,

on the Balaton extension) is the most problematic soil type in terms of both cellar damage

and construction. Loess

bank breaks in large areas (eg Dunaföldvár,

Dunaújváros, the eastern basin of Lake Balaton) are known, and each year the level

requires one or two deaths

due to improper

construction of the loess.

The most damaging feature

of a typical loess is its collapse. This

process usually starts with water.

The main reason for the collapse lies

in the structure of the loess. It

contains SiO2 as its main constituent, along with feldspar,

carbonates and mica. Typical loess in our country consists of dust and sand carried

and deposited by the wind in the

Holocene (that is, very close to

our time in geological history). Changes in the Ice Age, during

the warmer periods, resulted in vegetation settling on the loess,

with tubules left in place of dead bodies, making

the loess macroporous. Water or a significant load causes these

tubes to collapse and lime to dissolve. This causes the loess

to suffer up to 55-60% volume

change (collapse). In loess, collapse occurs on vertical

and oblique free surfaces, which is why the

entrance part of the cellars is endangered. In such cases, the

cellars are dug deeper and deeper into the stomach

of the mountain. Bertalan Andrásfalvy

describes in his study of the Páty Cellar Mountain that a cellar carved in a loess is known to have entered its full length

under a manhole, as it was

originally.

Loess on the surface is characterized by blocky breaks, and cellars have coffin-shaped

tears and detachments. The latter lead to a severe, often fatal

disaster.

The destruction of the

loess cavities is rapid. One day, there

are only a few cracks that

can break in a few hours or

a day.

From the point of view of cellar hazard prevention,

it is important to know that

although some of the cellar passages

cut in the old days have been

destroyed today, the collapses never

fill the underground space in their entirety and, therefore, sinking or cracking

is not excluded.

The other two types of Hungarian loess, the good

loess on the soil, and the

properties of the infused loess prevalent

in the Great Plain, differ from the

above and do not pose the

same risk as the typical

loess. But the cellars established

in them have the same damage

as the clay

cellars discussed earlier.

The entrance

of the cellar carved into a loess

with a broken wall

Kalazno, Tolna County

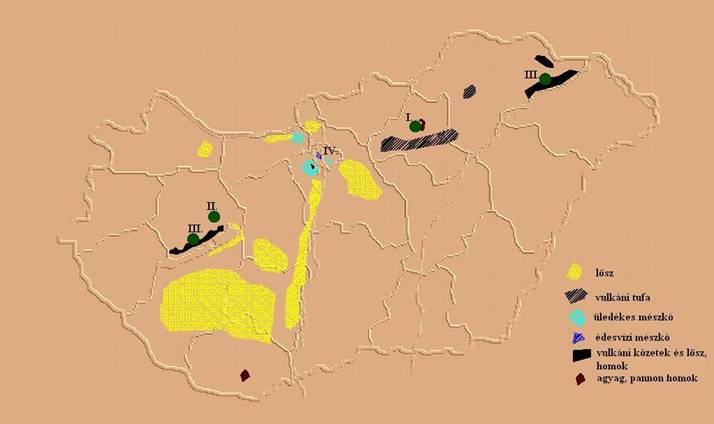

4.2. Occurrence of some

major rock types (look in hungarian page)

4.3. Relationships between

the surrounding rock environment of cellars and the appearance of cellar damage

The following factors

should be considered when determining the appearance of cellar damage and how to treat

it:

1. The maximum depth of underground cavities and cellars subject to cellar

hazard prevention is approximately 25 m, therefore, in

addition to rock examination in mining, the methods of engineering (civil engineering) soil mechanics and geotechnics should be applied. The reason for this

is that most of the endangered cellars are made of materials

(eg clay, loess, spill rocks)

that deep-water mining does not encounter.

2. The shear strength

of rocks surrounding cellars and cavities is significantly reduced by the cracks

in them and the softer materials that fill them

(typically clay).

3. Moisture content

of the surrounding rocks is also a factor that reduces

stability. Soaking moisture or pressurized

water in the rock affects stability.

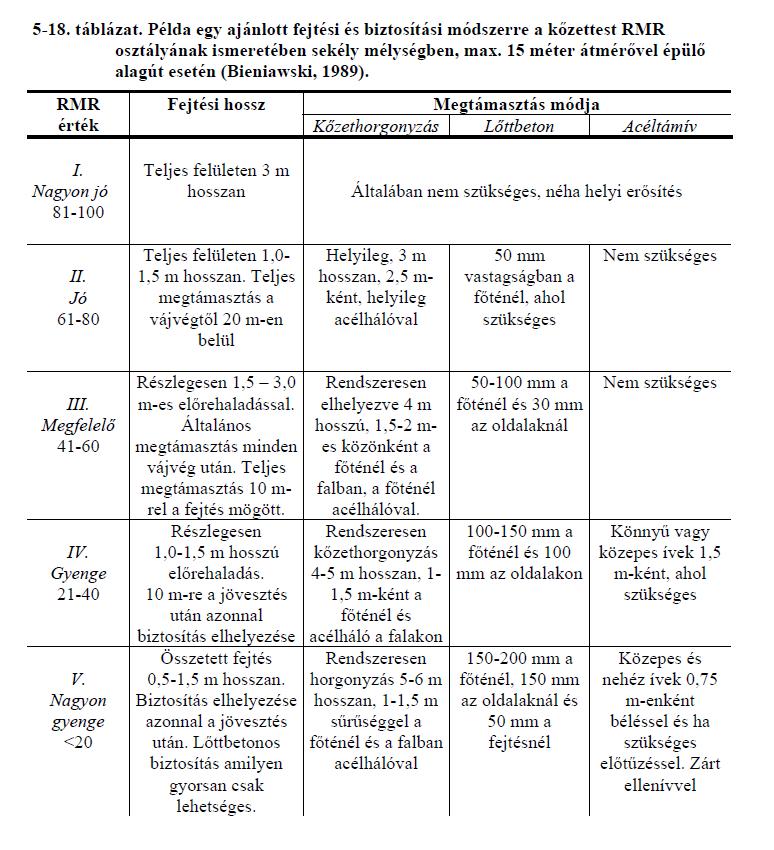

4. In Hungary, the so-called

so-called Qualification for the classification

of rock bodies is currently

developed in engineering practice. The application of RMR

is the generally accepted method. The essence of RMR is to measure, classify, and then aggregate the following six

properties of boundary rocks:

- uniaxial rock compressive

strength (σc)

- rock body breakdown index (RQD)

- distance of the

rock body (Jn)

- state of articulation

surfaces (Jr)

- water conditions,

groundwater and groundwater

(Jw)

- direction and location

of partitions (Or)

Taking into account

the above with different weights, it sets

5 classes of rocks and assigns them different

types of support and freely extending cut lengths.

The method is primarily

designed to drive new cuts, but

can be used with some additions

and modifications to test existing cellars, cavities without support structures, and to determine the

work to be performed.

The author of this

site has prepared a modified

version of the RMR method for existing cellars.